Boeing took the curtain off its proposed commercial spacecraft this morning, allowing a limited number of press and media into one of its Houston facilities to crawl around inside a high-fidelity mockup. The spacecraft, designated the CST-100 (for "Crew Space Transportation"), is a large capsule, resembling a scaled-up version of the iconic Apollo command module.

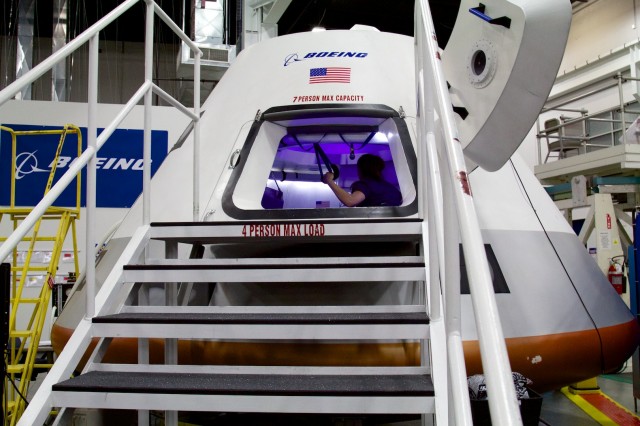

The CST-100 mockup on display at Boeing's Houston Product Support Center in Clear Lake, TX.

The CST-100 seats up to seven astronauts and will primarily be used to transport people to and from destinations in Low Earth Orbit ("LEO"), such as the International Space Station. CST-100 is designed specifically as a LEO transport, but Low Earth Orbit is only one of a much larger set of potential destinations that Boeing and other commercial space flight companies hope to target, extending all the way out to interplanetary space. According to Boeing Space Exploration Vice President and General Manager John Elbon, each destination has its own set of requirements and challenges. So CST-100 is Boeing's attempt at creating a spacecraft specifically designed to be a LEO workhorse.

The capsule itself sits bedecked with ladders and cameras elevated on a stand in the high bay of Boeing's Houston Product Support center. When the press first approached the spacecraft, astronautSerena Auñón was still strapped into one of the mockup's two seats, performing an evaluation of how her bright orange ACES flight suit worked with the spacecraft's internal layout. The press quickly mobbed her when she emerged from the craft and stepped down the ladder. When asked, Auñón reported that she was pleased with the cockpit and the work done so far.

NASA astronaut Serena Auñón emerges from testing the orange ACER suit inside of the CST-100 mockup.

The ship

CST-100 isn't the only capsule-shaped spacecraft attempting to make its way into orbit these days. NASA's official successor to the space shuttle is the Orion Multi-Purpose Crew Vehicle, designed and manufactured for NASA by Lockheed Martin. The Orion MPCV itself evolved from the 2006 "bake-off"Crew Exploration Vehicle competition between Lockheed Martin and Boeing; Lockheed Martin ultimately beat Boeing and won the contract.

Some amount of Boeing's CEV capsule design work evolved into today's CST-100, but the new vehicle shares no common hardware with the CEV concept—it was developed separately under NASA's Commercial Crew integrated Capability program (or "CCiCAP," as it's called). Boeing's CST-100 is one of three spacecraft being developed for the program, with the other two being Sierra Nevada Corporation's Dream Chaser lifting body craft and SpaceX's Dragon capsule (which has already successfully flown to space and docked with the ISS, albeit in an unmanned configuration).

CST-100 eschews the space shuttle's tile-based thermal protection system, instead using for its heat shield a phenolic resin-based structure that burns away ("ablates") during re-entry. This approach is also used by the Orion MPCV and avoids the tremendous touch-labor expense that the space shuttle's tiles incurred prior to every launch. The craft is reusable too. After a mission it is designed to be refurbished and refitted and relaunched up to 10 times. This makes it more flexible and cost-efficient than the original capsules of the 1960s, and at the same time it avoids incurring the huge total refit costs that the space shuttle brought with it.

In the cockpit

I slipped on the required blue paper surgical booties and scrambled up the ladder ahead of the rest of the journalists, since unlike most of them, I hadn't brought along a film crew and tons of equipment. The hatch was a narrow affair, and I quickly found myself puzzled at how Auñón wiggled into the spacecraft in her bulky ACES suit—I was having a hard enough time in slacks and a dress shirt. Once inside, the space was extremely tight, and I found myself wishing I'd brought a wider lens; I tried to picture cramming seven astronauts and their suits and gear into the space. Microgravity would make it a lot easier, of course, but it would definitely be a crowded ride.

The interior of CST-100, seen from the hatch. This space is intended to hold up to seven astronauts—though in microgravity, it'll seem a lot bigger.

Most of the items in the mockup's interior are themselves mockups; the control panel was present but mostly made up of nonfunctioning switches and colored cardboard and paper buttons. I gamely slid my way into the commander's seat and posed for pictures, then squirmed out and made way for the other journalists. The interior was dominated by struts and stowage bags, though there were convenient blue-colored hand-holds placed throughout that we all had to use to drag our way over each other, with many mumbled "excuse mes" and "sorrys."

I squeezed into the lower deck and snapped this shot aiming up at the two seats. There was not a lot of space to move around inside the mockup.

BRB GOING TO SPACE

Cheaper and off the shelf

Cost savings is one of the largest driving forces behind the spacecraft's design—second only to safety. As much as possible, the CST-100 capsule uses "COTS" components (a popular aerospace acronym standing for "Commercial, Off-the-Shelf"), even in its avionics. Boeing Space Exploration vice president (and former astronaut) Chris Ferguson spoke in detail about the control consoles and instrumentation Boeing is planning on using for the CST-100. The plan is to equip astronauts with an "electronic flight bag," much in the same way that commercial airline pilots these days are being equipped with iPads and other consumer tablet hardware for all of their checklists and documentation.

Ferguson explained, in fact, that Boeing plans to use the same type of commercial touchscreen hardware—iPads, or Microsoft Surface tablets, or Android tablets—whichever company is willing to work with Boeing on the design. "If Apple comes to us and says 'Hey, we want you to use our product, and we're willing to do this and this and this,' well, hey, a tablet's a tablet, really!" he said. One of the big factors, though, is matching existing systems on the International Space Station and also upcoming flight systems in the Orion MPCV. Boeing wants there to be as much commonality as possible, so crews will be able to switch between spacecraft and space station without needing huge amounts of additional training. But as far as looking like previous spacecraft, like the space shuttle, CST-100 will be very, very different.

Boeing VP (and former astronaut) Chris Ferguson.

"All the hardware switches you see in there are backup and are never intended to be used normally," Ferguson went on. The cockpit contains hardware switches for all critical systems—opening and closing valves, for example—but the intent is for the crew to be able to fly the spacecraft and do all of its operating tasks through touchscreens. Or to not have the crew do those tasks at all—CST-100 is being designed with the capability to operate totally autonomously, unlike the space shuttle. The latter lacked the ability to be fully operated remotely (though that capability was added in 2006 with the addition of a special cable).

I asked Ferguson about the practicality of operating touchscreens in gloves, since the crew would likely spend their launches and landings in the same orange ACES suits being used by Serena Auñón. He replied that Boeing is investigating including a capacitive mesh layer in the fingers of the suits, sort of along the same lines as the "iPad gloves" folks in northern climates can buy to keep their fingers warm while they poke at their gadgets (though, obviously, much more air-tight and spacesuit-y).

Getting there and back

Boeing plans to have the CST-100 hitch its initial rides into orbit on the Atlas V rocket, coupled with aCentaur upper stage. The combination has an excellent safety record, and Boeing (with assistance from its United Launch Alliance joint venture) will be taking the extra steps necessary to "man-rate" the rocket—that is, prove by NASA's stringent guidelines that the rocket is safe enough to carry humans, rather than the cargo it's currently used for.

Atlas V isn't the only rocket with which CST-100 will be compatible; Boeing is designing the capsule to work with a wide variety of launch systems, including rival SpaceX's Falcon 9 rocket. It's even possible that the CST-100 could be lofted by NASA's ultra-heavy-lift Space Launch System when or if it becomes available, though using that large a rocket to lift the CST-100 capsule would be overkill.

Watching astronaut Auñón on the monitors placed outside the mockup.

It's also necessary for Boeing to construct an escape system for the CST-100, so that the vehicle can keep its crew safe in the event of a launch abort. Early NASA capsules used Launch Escape Systems—a smaller rocket perched on the capsule's nose that could drag the capsule away from the rocket if something went wrong. The space shuttle lacked any notable external abort system, relying instead on fancy flying in the event of an emergency. CST-100 will have a "pusher escape system," using four rockets in the CST-100's service module to haul the capsule off and away from the launch vehicle. This design has the added benefit of also bringing some extra usable propellant to orbit; tower-based Launch Escape Systems are typically jettisoned after a certain point in the launch, but CST-100's abort engines and their propellant are also intended to be used for on-orbit maneuvering.

The commercial future

One of the odd facts about the "commercial space flight" push is that manned space flight has alwaysbeen a "commercial" endeavor. Companies like Boeing have built every rocket and spacecraft that NASA has ever flown. The new efforts of Boeing, SpaceX, and others would be better characterized as commercially available or commercially funded (though even that isn't quite accurate, since NASA is splitting more than a billion dollars between Boeing, SpaceX, and Sierra Nevada Corporation for them to develop their CCiCap craft). Boeing is an old hand at the spaceship game—but being that old hand brings with it complications. When compared with a nimble, young company like SpaceX, Boeing can seem stodgy—even moribund, bound up in processes and meetings over even tiny details.

John Mulholland, Boeing's Vice President and Program Manager of Commercial Operations, acknowledged the difficulty Boeing faces with its approach. Still, he remained hopeful. "The nice thing is that we're coming into this from a position of experience," he said. "We understand the processes and what was done on previous human spaceflight designs, and having that knowledge, we can look at areas where we can drive efficiency, without sacrificing reliability or safety." He spoke further on a renewed focus within Boeing on both "decision velocity" and "decision stability"—making correct decisions quickly and sticking with things that work.

"I think we're doing a great job of it," continued John Elbon, who heads Boeing's entire Space Exploration group. "We aren't as vocal and out there as maybe some others, but Mulholland has put together a relatively small team to do this, and the effectiveness we're seeing relative to how much it's costing us to do this and how many hours it's taking is amazing."

The CST-100 is currently winging its way through the design review process. Boeing is hopeful that the capsule will fly in 2015 or 2016.

No comments:

Post a Comment

Let us know your Thoughts and ideas!

Your comment will be deleted if you

Spam , Adv. Or use of bad language!

Try not to! And thank for visiting and for the comment

Keep visiting and spread and share our post !!

Sharing is a kind way of caring!! Thanks again!